How I Cast Gold, Platinum and Sterling Silver for My Custom Jewelry Designs

I often have clients who are curious about the process of how I create my custom jewelry designs from drawing to casting and finally the finished piece. This guide will give you the brief idea of the basics of how the process works and take you through the general 6 steps of how I cast my gold and silver jewelry designs.The Tools, Machinery and Equipment I Use In My Design Shop:

• Unvulcanized Rubber Molding Compound

• Bladed Instrument

• Injection Wax

• Wax Melter

• Wax Injector

• Casting Flask

• Gypsum-Based Investment Mold Material

• Kiln

• Gold or Silver

• Hammer

• Abrasive Wheel

• Casting Machine

• Pouring Crucible

Process 1

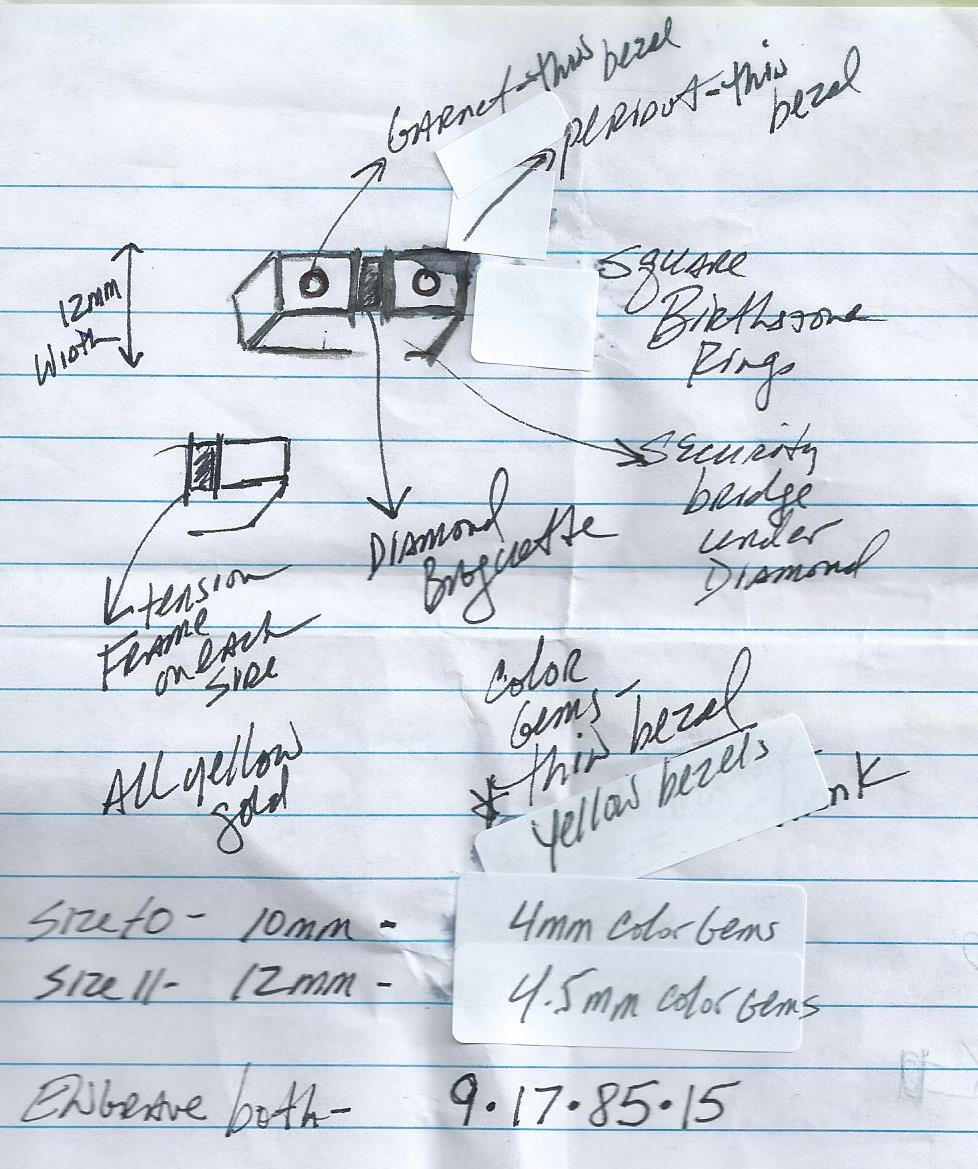

With my original one of a kind design from drawing to handmade wax model for casting I am beginning the custom jewelry design process. The first step is to hand carve a detailed wax model from the conceptual drawing that I created after working with my client. A fitting of this model with the client is set up and once approved this will ultimately be the piece of jewelry that I will create. All wax models must be perfect according to the clients wishes and approved by to proceed for the next steps.

Process 2

This next step in my opinion for one of a kind jewelry design is the most important. It is the creation and essence of the actual design and it called "The Lost Wax Process". Using a bit more melted wax I ensure the model is propped up and secured to the bottom of the casting flask. I place the entire flask into the kiln oven will harden the mold and melt away the wax. This leaves a hollow chamber in the center of the cast jewelry mold in this lost wax process.

Process 3

Now I am starting to pour the casting and according to the design I am creating, I only melt an appropriate amount of either gold or silver in an appropriate pouring crucible and use an appropriate casting machine for this part of the process. I continue by injecting this molten liquid gold, platinum or sterling silver from the pouring crucible into the mold through the hole that was left by the “now” melted wax support stick. Finally allowing this metal to cool down before continuing.

Process 4

At this point when the jewelry piece is hardened and cooled down, I am ready to set diamonds and gemstones according to the specific design I am creating.

Process 5

I am ready for polishing and finishing of any irregularities on the jewelry and to create a texture to the design according to my conceptual drawing. Depending on the intricacies of the piece I select the appropriate buffing wheel to buff out the imperfections and irregularities that may have been present after the casting process. I continue to set diamonds, gemstones and everything beneficial including textures and special finishes that the client requested in my one of a kind jewelry design.

Process 6

Finished product, a beautiful and unique one of a kind custom design by MARCO.